Airflow Range: 300 ~52000 m3/h (176 ~30606 CFM)

Static Pressure Range: 100 ~ 700Pa (0.4 ~2.81 in WG)

Drive Types: Direct / Belt drive / VFD

Mounting Types: Rooftop curb mounted

Applications: 1. General ventilation exhaust

3. Explosion-proof air exhaust

4. Smoke removal

Detailed Specifications

Wheel Technology

-

Unique and Innovative Design

The centrifugal wheel specially made for rooftop fans in all-aluminum construction

Innovative design based on the advanced foreign concept of full control over flow passages

Leading-edge products in efficiency and sound

Wide performance range of high efficiency and non-overload

-

Internationally Advanced Process Adopted for Better Alignment with Flow Field Characteristics

Flow passage components formed by spinning not by traditional process

Blades formed by punching to ensure quality

Dedicated fixtures and tools to ensure the precise mounting position of blades

-

Carefully Selected Materials, Suitable for Smoke Removal and for Use in Coastal Regions

The strength made for a minimum of 200% of the highest running speed to perform the smoke removal duty

Resistance to neutral salt spray for wide use in coastal regions

Rigorous tests for trust worthy performance

-

4th Generation of Wind-Surfer Wheel

Continuous improvement for better performance

Higher energy efficiency

Lower sound for quieter operation

-

Light Weight and All-aluminum Construction with Explosion Proof Properties

Metallic feeling and top-notch appearance

Light weight, weighing only 1/3 of traditional products

Spark A spark resistance construction, aluminum housing and aluminum wheel and aluminum inlet cone (AMCA99-10)

General Features

-

Upblast exhaust:

Reduce consistence of contamination, automatically separate and collect the liquid contaminated material to keep the roof clean.

-

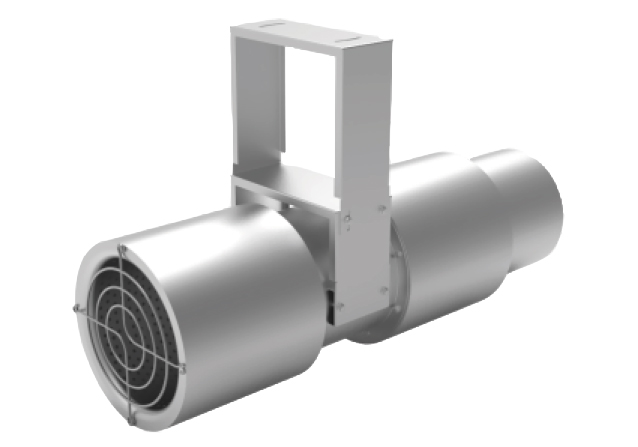

Independent Motor Chamber: Super Long Service Life

Drive mechanism located in an independent chamber to have zero contact with the airstream

Use for exhaust of air containing volatile engine oil, cooking fumes, dust and organic solvent

Great reliability and expected service life of over ten years

Fresh air shall be taken into the motor chamber to cool down the motor. The air shall be directed through the clearance under the motor cover.

-

Patented Appearance Design for Practical Beauty

Smooth and elegant appearance design with fine manufacturing process

Silver housing of metallic feeling that easily matches different colors of buildings

Buildings added a streak of modernity and nobility

-

Light Weight: Especially Suitable for Rooftop of Light Gauge Steel Construction

Load on the rooftop reduced with less investment in steel

Housing and wheel constructed of aluminum alloy

Technical Information

- Quality Standards

The fan has designed according to AMCA design procedure, The fan is certified in according with UL 705 standard. The products are produced within very control procedure following ISO 9001, ISO14001 and ISO 45001.

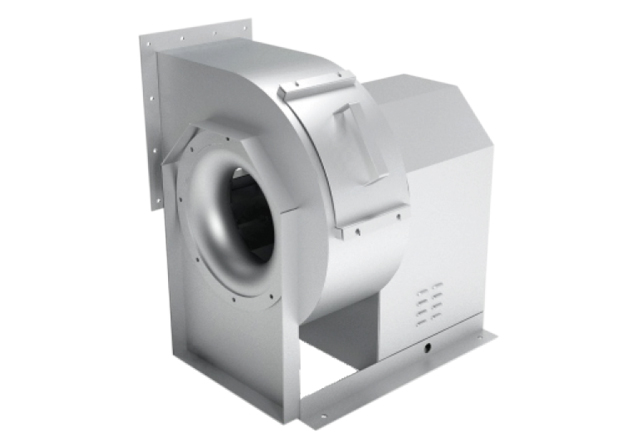

- Fan Type

Fan shall be rooftop upblast centrifugal exhaust type and the drive type shall be direct drive or belt drive. The wheel shall be made of aluminium backward inclined centrifugal wheel, and shall include a wheel cone carefully matched to the inlet venture for precise running tolerances. The wheel shall be statically and dynamically balanced to Level G2.5 as per AMCA204 standard.

- Fan Housing

The fan housing shall be constructed of heavy gauge aluminium alloy panel with a rigid internal support structure. The wind band support structure shall be strong enough to protect the fan from wind load, the internal structure shall be water tight during heavy rain or snow melting. The exterior colour of the fan shall be silver white (Option: epoxy coating, colour RAL9006).

- Motor

The motor shall be carefully matched to the fan load. It shall be (IP55,IP56, …etc) rated with Class F,H Insulation according to project specification . The motor bearing shall be of ball type and lubrication- free. Out of the air stream shall the motor and drive mechanism be located to avoid grease or dirt accumulation.

- Internal wiring conduit

Fan shall be furnished with conduit to lead the power supply wiring through the curb to the motor chamber.

- Oil Drain

The oil drain is required to discharge the oil through drainage system without accumulating it inside the fan body that will help to keep the roof clean all the time.

- Nameplate

A permanently fixed aluminum nameplate shall clearly display the fan number, product model and serial number (a unique ID for each fan) so that the parts used can be traceable by customers.

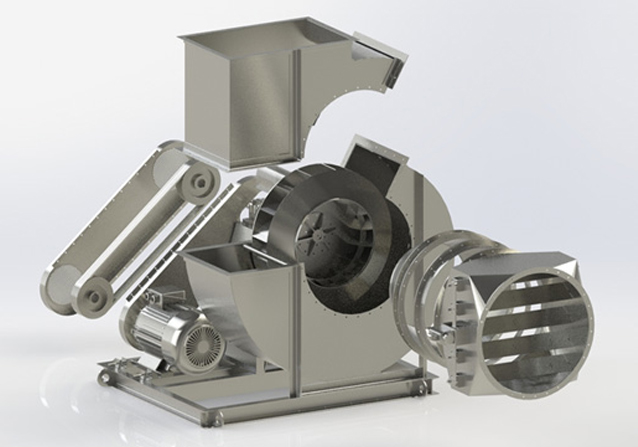

- Drive Mechanism (For belt drive type only)

|

Fan Part |

Description |

|

Shaft |

Fan shaft shall be heat treated through soaking furnace to reach the hardness level of HB250, and the surface shall be hard film corrosion treated. The fan shaft shall be balanced together with the wheel, and the shaft design speed shall at least exceed 25% of the maximum fan operation speed.

|

|

Bearings |

Metal bearings shall be used to support the fan shaft to avoid vibrations directly coming onto the motor. The bearing life shall be (80, 000 to 150,000) hours at the maximum operating speed specified in the catalog as per the design. The bearing shall be of permanently sealed type and metal pillow block ball bearing that can be lubricated.

|

|

Drive Support |

Drive assemblies shall be supported by heavy gauge powder coated steel. Fan shaft shall be precisely turned, heat treated and balanced. The shaft design speed shall exceed 25% of the maximum fan operation speed.

|

|

Pulley |

Fan pulleys shall be sized for a minimum of 150% of the driving power. Pulleys shall be cast iron, keyed and securely attached to the wheel and motor shaft. Conical type bushings shall be equipped for easy removal of the pulley.

|