Airflow Range: 2,600~116,800 m³/h (1,529~68,706 CFM)

Static Pressure Range: 50~850 Pa (0.2~3.41 in.WG.)

Drive Configurations: Direct

Installation Methods: Vertical/ Horizontal/ Ceiling Hung

Applications: Fire & Smoke/ Two-Speed Fume Extraction

Certification: CCCF, EG

Detailed Specifications

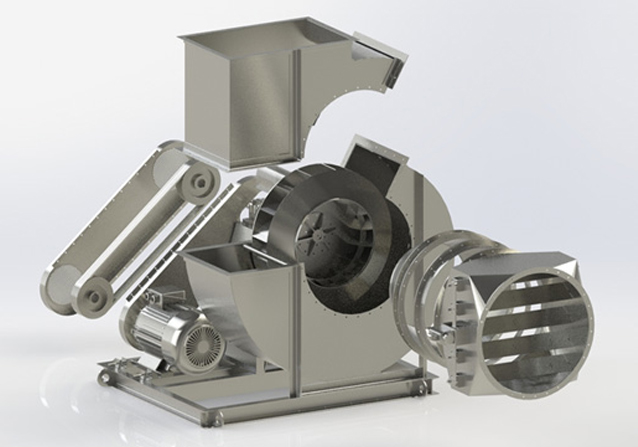

Impeller Technology

-

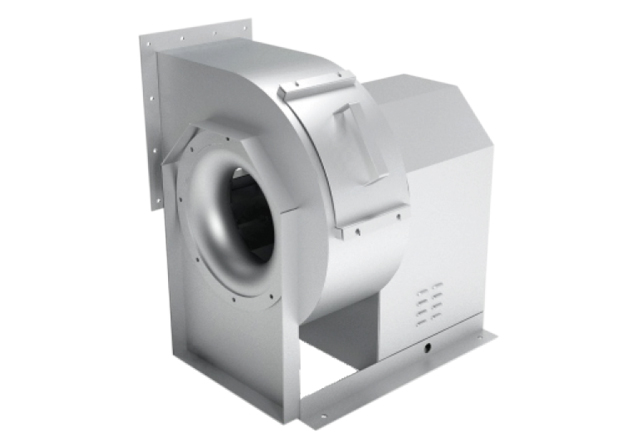

Fan Type

-

To adopt optimum aerodynamic characteristics of the wing type vanes.

-

Streamlined impeller hub type design.

-

Optimized design of CFD flow field simulation and experimental verification repeatedly.

-

Advanced process to ensure clearance of the impeller and cylinder.

-

High efficiency saves the operation cost.

-

Reliable Structural Design

-

Advanced casting process to ensure the accuracy and stability.

-

Computer-aided design of CAD for optimizing repeatedly.

-

High strength of the spiral impeller hub makes the operation more reliable.

-

Innovative hub connecting structure makes the operation safely.

-

High Balancing Level

-

Balance level up to G2.5.

-

To reduce the vibration of the fan operation, to improve reliability.

-

To reduce the running noise.

General Features

-

High Reliability

-

Optimized design of FEA and experimental verification repeatedly.

-

Core component adopts casting process to improve the strength.

-

Mold a molding, high precision and good consistency.

-

High balancing level makes the running more smoothly.

-

High Efficiency

-

To adopt optimum aerodynamic characteristics of the wing type vanes.

-

Smooth the spiral wheel hub to reduce turbulence.

-

Advanced process reduces clearance of the wheel and cylinder to improve efficiency.

-

Be equipped with guide vanes of the wheel.

-

Advantages of direct drive: efficient, maintenance-free

-

Higher transmission efficiency.

-

No wearing parts, low maintenance.

-

Easier and more effective of maintenance.

-

Sealed self-lubricating bearing for motor, increasing service life.

-

Compact design to save installation space.

-

General air supply& exhaust

-

Explosion-proof supply& exhaust.

-

Positive pressure air supply, Smoke removal duty.

-

Two-speed supply& exhaust.

-

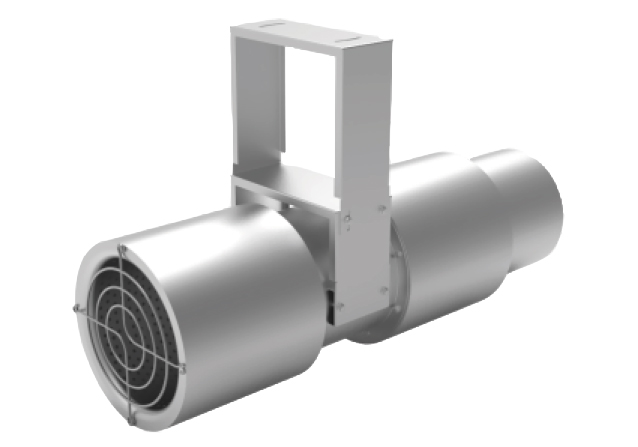

Convenient and flexible installation

-

Floor-mounted: horizontal or vertical.

-

Ceiling-mounted: horizontal or vertical.

-

Rooftop: Outdoor roof installation with flag-cloud wind band.

Technical Information

-

Quality Standards

The fan has designed according to AMCA design procedure, the products are produced within very control procedure following ISO 9001, ISO14001 and ISO 45001.

-

Coating

Fan surface shall be polished and cleaned up to remove particulates, welding slag, burrs, sharp edge, iron, oil, then epoxy coating [options: colour changes are available], fan surface shall be free of sags, wrinkle, blisters, exposed metal or peeling after coating. It shall be no corrosion and rust at least 5 years in allowable working condition.

-

Fan Type

The fan shall be the axial flow fan with cylindrical structure. The drive type shall be direct-drive.

-

Motor Chamber with Cooling System

Motor shall be installed in a special motor chamber, which isolates the motor from the exhaust air stream to avoid the influence of high air temperature. This chamber shall have special air channel, suck in fresh air from outside of the fan to cool the motor.

-

Main Fan parts

|

Fan Part |

Description |

|

Impeller |

It shall reach the static and dynamic balancing level of G2.5 per AMCA 204 standard. The wheel shall have precise running tolerances for maximum performance and operating efficiency.

|

|

Fan Housing |

Fan housing shall be constructed of cold rolled steel. The surface shall be anti-corrosion treated, and the flange shall be fabricated from the casing material for strengthening.The housing thickness shall be adequate to ensure the structure rigidity after motor installed.

|

|

Motor |

The motor shall be carefully matched to the fan load. It shall be (IP55,IP56, …etc) rated with Class F,H Insulation according to project specification . The motor bearing shall be of ball type and lubrication- free.

|