Airflow Range: 4,000~230,000 m³/h (2,353~135,294 CFM)

Total Pressure Range: 30~2,000 Pa (0.12~8.03 in.WG.)

Drive Type: Direct drive

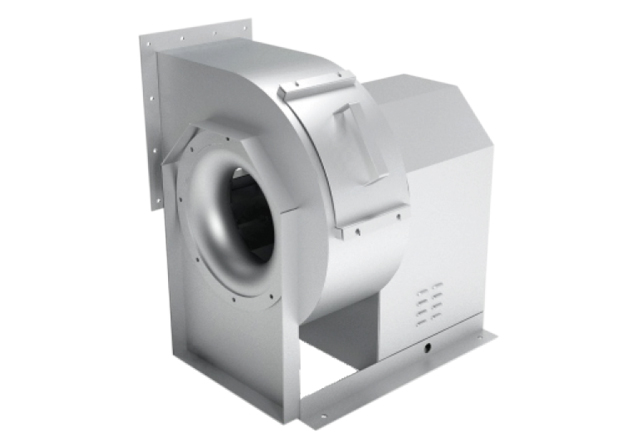

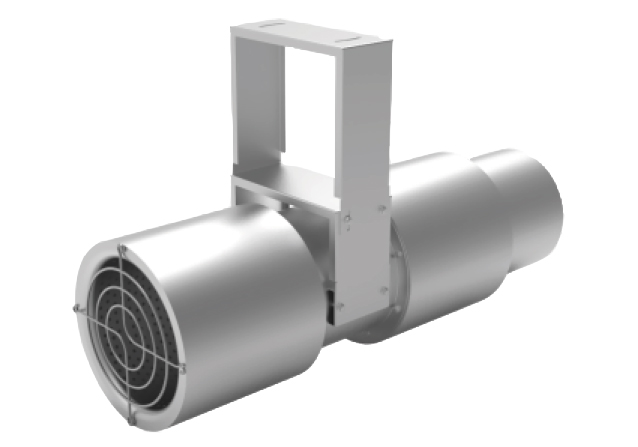

Mounting Types: Base mounted/ Ceiling hung

Applications: General air supply and exhaust/ Explosion-proof air supply and exhaust / Positive pressure air supply/ Smoke removal

Detailed Specifications

Impeller Technology

-

High-efficiency Air Performance

Airfoil blades of optimum air performance.

Vortex hub design.

Optimized design through CFD simulation and experimental verification.

Advanced process used to reduce clearance between the impeller and the cylindrical fan body.

High efficiency and lower operation costs

-

Unique Hub-to-Tip Ratio

Hub-to-tip ratio as high as 0.56.

High pressure rise rates to improve airflow capacity.

Reducing airflow loss caused by insufficient pressure.

Particularly suitable for long distance airflow delivery.

-

Reliable Structural Design

Advanced casting process to ensure the accuracy and consistency.

Optimized CAD through repeated tests.

Vortex hub of high-strength and greater reliability.

Innovative hub connection that makes operation safer.

-

High Balance Quality Grade

The balance quality grade as high as G2.5.

Vibration reduced and reliability improved.

Sound greatly lowered

-

Variable Angles Available

14 impeller sizes in total ranging from 315 to 1400 mm.

8 blade angles in total from 0 to 35 degrees.

4 speeds in total determined by four poles of 2/4/6/8.

Optimized model selection to help reduce upfront investment and operation costs.

General Features

-

High Efficiency

Airfoil blades of optimum air performance

Vortex hub that smooth the flow of air and reduces turbulence

Advanced process used to reduce clearance between the impeller and the cylindrical fan body for greater efficiency

Guide vanes mounted behind the impeller.

-

Great Reliability

Optimized design through the FEA method and experimental verification

Casting process used for core components and high strength achieved

Die forming technique for better accuracy and consistency

Higher balance quality grade and more reliable operation.

-

Direct Drive, High Efficiency and No Maintenance

Airflow delivery of higher efficiency

No quick wear parts and low maintenance

Easier and more effective maintenance

Sealed and lubrication-free motor bearing for longer service life

Compact design and space-saving installation.

-

Applications

General air supply and exhaust

Explosion-proof air supply and exhaust

Positive pressure air supply/ Smoke removal

Two-speed air supply and exhaust

-

Convenient and Flexible Installation

Base-mounted: horizontally or vertically.

Ceiling-hung: horizontally or vertically.

Roof mounted: outdoor installation with the Fag-Cloud TM weather hood.

-

INFI-COAT Modular FilmTM coating, unfading over time

Pickling, Parkerizing and alkaline wash combined to ensure a clean surface.

High-adhesion from being processed in the high temperature furnace.

Resistance to uniform corrosion over large areas and localized pitting corrosion.

Technical Information

-

Quality Standards

The fan shall be tested and certified in accordance with AMCA Standard 210 & 300, TUV EN 12101-3 for smoke application. AMCA Seal for (Efficiency Sound, Air Performance and Fan energy index FEI) shall be tagged on each fan before leaving the factory as a standard seal, for other seals shall be tagged on the fan according to application and customer needs.

The manufacturer shall obtain Production License for National Industrial Products and be certified by ISO 9001, ISO 14001, ISO 45001.

-

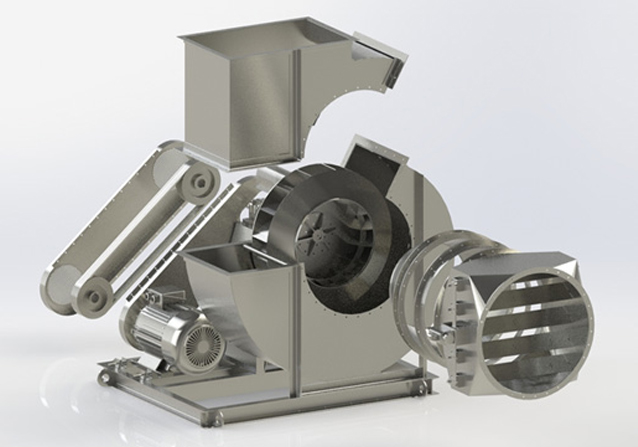

Fan Type

It shall be vane-axial fan with airfoil blades. The fan shall be direct driven and in a cylindrical structure. Behind the impeller in the cylindrical body, there shall be guiding vanes for airflow straightening. The guiding vane shall have a three-dimensional curved surface in line with flow field characteristics for better air performance and static efficiency.

-

Surface Processing

The surface of the fan shall be polished to remove any protuberances, welding spatters, burrs, sharp edges and scrap iron. Then it shall undergo the processes of oil removal, pickling, and applying putty before being finished with electrostatic epoxy coatings processed under high temperature for strong adhesion. The surface shall be a level one without sags, cracks, cockles or detachment to avoid corrosion over a long period of time.

-

Main Fan parts

|

Fan Part |

Description |

|

Impeller - Type M |

It shall be an axial impeller with airfoil blades of variable angles to ensure that right models can be selected for various operating conditions. The impeller shall have a vortex hub to avoid turbulence and airfoil blades of optimum air performance. Stable airflow and low noise shall be ensured at the maximum running speed. Die casted Aluminum, the hub and blades shall be strong enough to maintain operational reliability and safety at a speed 120% of the maximum speed. The impeller should be subject to dynamic balancing tests up to AMCA 204- G2.5 balance quality grade so that its operational stability can be improved and service life extended.

|

|

Fan Housing |

The fan housing shall be made of quality carbon steel and continuously welded and use lap joint flanges. For the fan housing with the impeller diameter of less than 500mm, the carbon steel thickness should be no less than 2mm, For the fan housing with the impeller diameter between 500 and 1000mm, the carbon steel thickness should be no less than 2.5mm; For the fan housing with the impeller diameter of over 1000mm, the carbon steel thickness should be no less than 3mm. All these are to ensure the fan’s operational safety and reliability over a long period of time and extend its service life.

|

|

Motor |

It shall be of B5 or B14 installation type. The motor is (IP55,IP56,…etc) rated as per specification with Class F Insulation (Class H Insulation for Smoke Removal) and Temperature Rise Class B. Lubrication-free ball bearings shall be used. The coefficient of power reserve of the selected motor shall be over 110% to ensure safe operation. As the motor is located inside the fan, it is the supplier that shall provide the appropriate external junction box based on the actual application.

|