Airflow Range: 300 ~ 146,000 m³/h (176 ~ 85,882 CFM)

Airflow Range: 300 ~ 146,000 m³/h (176 ~ 85,882 CFM)

Total Pressure Range: 100 ~ 4,150 Pa (0.4 ~ 16.66 in.WG.)

Operating Temperature: -20 ~ 100 ℃

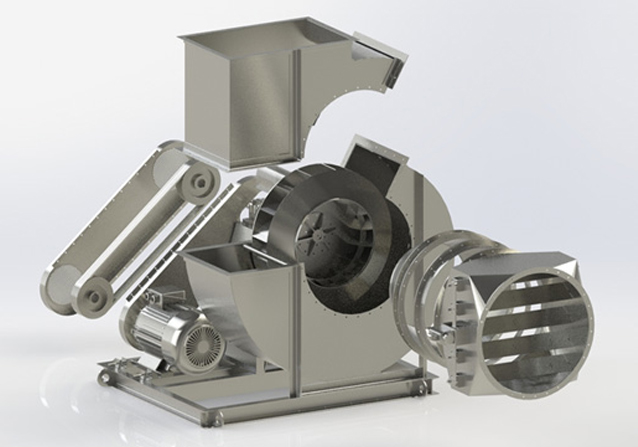

Drive Type: Belt

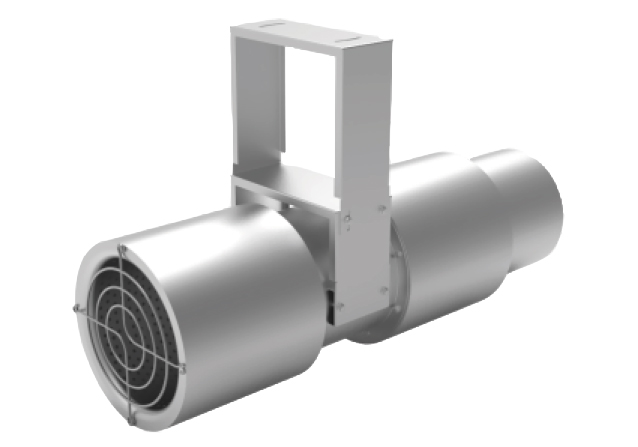

Installation Methods: Insertion

Applications: It can be directly inserted into the wall or other equipment. It is ideal for high temperature environment such as paint workshop where the paint job of the cars requires drying.

Detailed Specifications

Impeller Technology

-

Optimized Design

The fan adopts advanced technology. The design of backward curved centrifugal wheel is optimized by means of CFD hydro-field simulating. The design is more accordant with the aerodynamic characteristics, high efficiency, and stable airflow.

-

Advanced Process

All steel laser cut blades are welded and positioned accurately. The overall strength of the blades are designed and welded to withstand long hours high speed operation.

-

High Balancing Level

Each impeller is subjected to dynamic balance test. The balancing level is kept at G4.0 Durability, stability and quietness are guaranteed.

-

High performance Curve

The impeller has a stable, smooth air performance curve which can efficiently avoid performance drop caused by the deviation of the working point.

-

Surge Protection

The fan shaft power will not exceed the motor rated power regardless the operation point of the stable working range. Customers can use it without any worries.

-

Stress Analysis

Whole wheel is aided design of CAD, strengthen slots properly located and repeatedly validated to ensure long-term reliability of operation.

General Features

-

High Reliability

Our products use advance FEA-aided design to enhance the reliability of structure.

The hub and the impeller are strengthened and leak-proof thanks to the all-steel continuous welding method. Safety is also significantly improved during operation.

The new shaft and coupling technology ensuring the accuracy during the assembly process while maintaining high reliability.

Maximum load surpasses 35% of limit speed to ensure the long-term continuous operation of the security.

Bearing seal can be lubricated to ensure operation reliability and durability.

The drive unit has a protective shield using eye-catching warning color to ensure personal safety.

All our machines underwent vibration tests prior leaving the factory in order to achieve reliable and durable operation.

-

High Efficiency

Venturi inlet shall match the front disc precisely to avoid turbulent flow and air leakages, so that the air flows more smoothly to improve aerodynamic performance.

Optimized design repeatedly of CFD flow field simulation to ensure aerodynamic performance complied with the flow field characteristics.

Excellent aerodynamic performance.

Technical

Technical Information

-

Quality Standards

The fan has designed according to AMCA design procedure, the products are produced within very control procedure following ISO 9001, ISO14001 and ISO 45001.

-

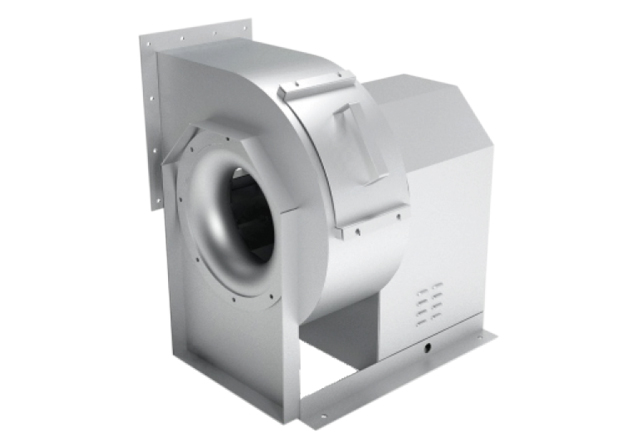

Fan Type

The fan shall be single-inlet with steel backward curved centrifugal impeller. The drive type shall be direct drive, coupling drive and belt drive. Structure of the fan shall be undone easily for maintenance and cleaning

-

Coating

Fan surface shall be polished and cleaned up to remove particulates, welding slag, burrs, sharp edge, iron, oil, then epoxy coating or high temperature coating for high temperature environments use, fan surface shall be free of sags, wrinkle, blisters, exposed metal or peeling after coating. It shall be no corrosion and rust at least 5 years in allowable working condition.

-

Main Fan parts

|

Fan Part |

Description |

|

Impeller Type (L or R) |

The impeller shall be steel backward-bladed centrifugal and fully welded. It shall be statically and dynamically balanced to level G4. Steady air-flow and noise should be minimal when the impeller is operating at the maximum allowable speed. The performance of the fan will not be affected because of the special characteristics of the impeller.

|

|

Fan Housing (Optional) |

The fan housing shall be made in steel and its thickness and strength should be able to withstand the maximum running weight of the fan. The volute shall be continuously welded and equipped with access door for removing possible foreign objects entered into the scroll.

|

|

Motor

|

The motor shall be carefully matched to the fan load. It shall be (IP55,IP56, …etc) rated with Class F,H Insulation according to project specification . The motor bearing shall be of ball type and lubrication- free. Out of the air stream shall the motor and drive mechanism be located to avoid grease or dirt accumulation.

|

|

Transmission Device |

Fan shaft shall be heat treated through soaking furnace to the hardness level between HB250-280, and the maximum load should be 35% higher than the maximum fan operational speed. Two bearings should be used to support the fan shaft. The service lifespan of them should be (80, 000 to 200,000) hours at the maximum operating speed specified in the catalog as per the design .It should be sealed and lubricated under normal temperature. The pulley shall be made of cast-iron and its construction size is determined corresponding to 130% of the driving power. The pulley and belt should be furnished with cover. The coupling shall be elastic coupling with cover as well. The safety of conveying power and torsion shall meet the design requirements.

|

|

Inlet (Optional) |

Fan inlet shall be aerodynamic design round curved section to transit the air to the wheel cone smoothly, it shall have good commutated effect to reduce turbulence, improve fan efficiency and reduce noise.

|